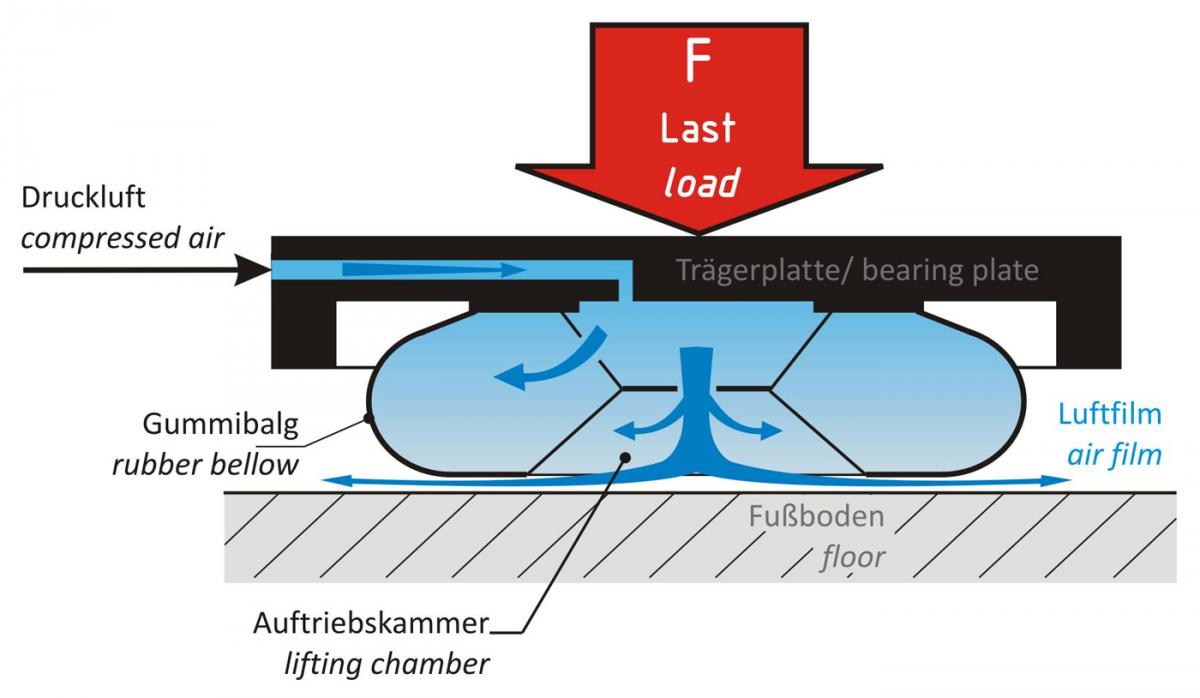

working principle of air cushions

Step 1 |

|

In the idle position the load rests on the floor. |

Step 2 |

|

When the air cushion is charged with compressed air, the ring-shaped rubber bellows inflates, sealing the interior from the floor. There, a pressure chamber forms, raising the load. |

Step 3 |

|

As soon as the air pressure in the chamber exceeds the counterpressure of the load, some air escapes into the surroundings of the bellows to form a thin film of air that causes the load to float. The load can now be moved almost without friction in any direction. |

Technical data

| Sizes: | Ø 150 – 1,400 mm (6" - 55") |

| Load capacities: | 150 – 60,000 kg (330 - 132,000 lb) |

| Lifting heights: | approx. 10 – 80 mm (3/8" - 3") |

| Operating pressure: | max.2 or 4 bar (35 or 70 psi) |

| Versions: |

- with integrated support plate - Explosion protected - Wear protection coating - Clean room version |

Data Sheet: Air cushion elements

Data Sheet: Air cushion elements